To become a reputable, leading international brand for laser applications

Each machine is carefully welded and spliced to ensure that the machine is more solid.

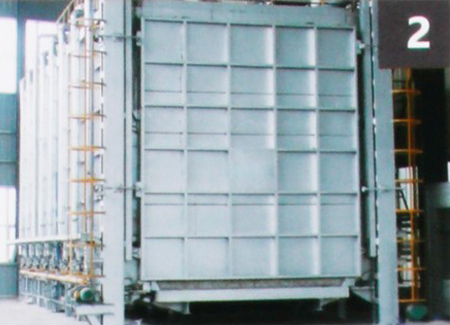

Every plate welding machine is subjected to high temperature heat treatment to relieve stress

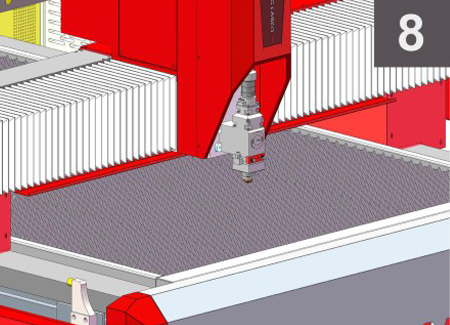

After annealing process, the machine is finished by gantry center milling

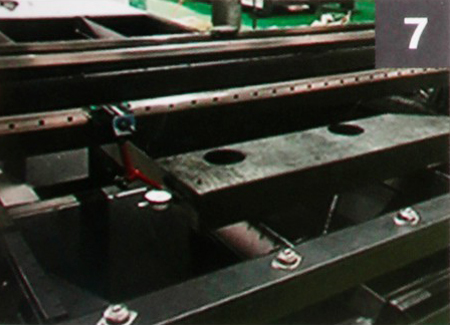

Each screw on the machine is tightly locked according to the standard torque

Laser collimator detects the straight line of guide rail

The precision of each rack screw point and two rack joints should be controlled within 0.01mm

The vertical accuracy error of X axis and Y axis is controlled within 0.01mm

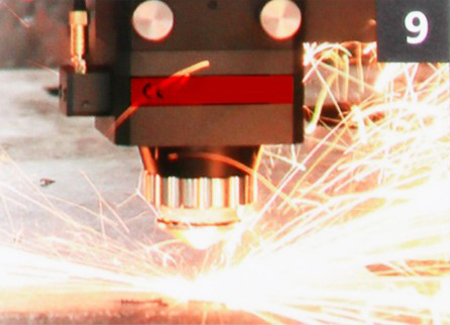

After installation and debugging, the laser interferometer is used for secondary calibration, detection and precision compensation

The equipment must be tested continuously for 72 hours before leaving the factory for strict testing

Wechat scan follow us

Copyright ? 2021 Zhongshan Jinzhi Laser Equipment Co., LTD 備案號(hào):粵ICP備17026665號(hào)-1